Following our Transparent Ocean Research Follow, Dr Junayed Hasan's illustrative presentation at Subsea Expo 2023 on ‘A Wider Blue Economy with an Emphasis on Acoustic Emission Based Condition Monitoring’, we’ve taken a closer look at how acoustic emission (AE) technology can help to detect pipeline leaks and the proposed approach to the challenges faced when using AE technology.

Detecting Pipeline Leaks

Pipelines are essential structures for transporting gases and fluids, but they are susceptible to leaks from factors such as corrosion, fatigue cracks and material defects. These leaks can lead to a plethora of issues, including economic losses, public safety hazards and environmental pollution. In order to address these issues, the pipeline industry is urgently seeking economical solutions, including repairing clamps and encapsulation collars instead of replacing the entire pipeline. To predict potential leaks, regular monitoring is vital and various techniques have been developed to detect pipeline leaks. Techniques include negative pressure wave analysis, accelerometer-based detection, magnetic flux leakage detection and acoustic emission (AE) technology.

Acoustic Emission (AE) Technology for Inspecting Pipelines

One of the most popular choices of the techniques mentioned above is AE technology. Often, when there is wear and tear within a material, a loud and obvious sound is created. Other times, these sounds are much more subtle and can only be detected though the use of specialist equipment. This is where AE technology comes in. AE is a non-destructive testing method for inspecting and monitoring the behaviour of equipment and materials performing under stress through the generation of transient elastic waves. Detection and analysis of AE signals can supply valuable information about the condition of a pipeline, leading to early leak detection, real-time response to degradation, ease of installation and high sensitivity. Moreover, it is a cost-effective approach for assessing large areas of materials and structures quickly and accurately, making it a versatile tool for condition monitoring.

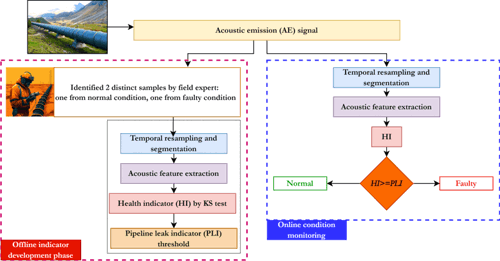

Similar to any test model, AE testing comes with a few challenges. Testing can detect if a flaw is present, however other testing methods are required to determine the extent of the flaw, for example the size and depth of a break. AE testing cannot be accurately carried out in loud environments and therefore makes it challenging to acquire accurate results without the use of additional technologies to filter out noise. To overcome this issue, Dr Junayed Hasan and his team have proposed a novel approach using acoustic emission event (AEE) features, two-sample Kolmogorov–Smirnov (KS) test, and several deep learning-based approaches for real-time pipeline leak detection.

The Approach

The proposed technique extracts AEE features from AE signals using a sliding window with an adaptive threshold so that the properties of both burst and continuous-type emissions can be retained. The AEE features form a distribution that changes shape when the pipeline condition changes from normal to leakage.

After this, the AEE feature distributions for leak and healthy conditions are discriminated using the two-sample KS test and a pipeline leak indicator (PLI) is obtained.

The experimental results show that the proposed PLI accurately distinguishes leak and no-leak conditions without prior leak information and performs better than traditional features.

To further utilise deep learning-based solutions for pipeline fault inspection, the technique also makes a suggestion for an automated data labelling process for industry. Thus, the team’s solution makes it possible to quickly test for leaks in large offshore structures.

To discover more about how our Transparent Ocean team is solving real-world problems where the solution can be significantly enhanced by mitigating risks and reducing the costs towards a net zero ocean, view our dedicated Transparent Ocean webpage.